Jet Repair Service - Konica Minolta KM1024 LNB

The Jet Repair Process

Inspection

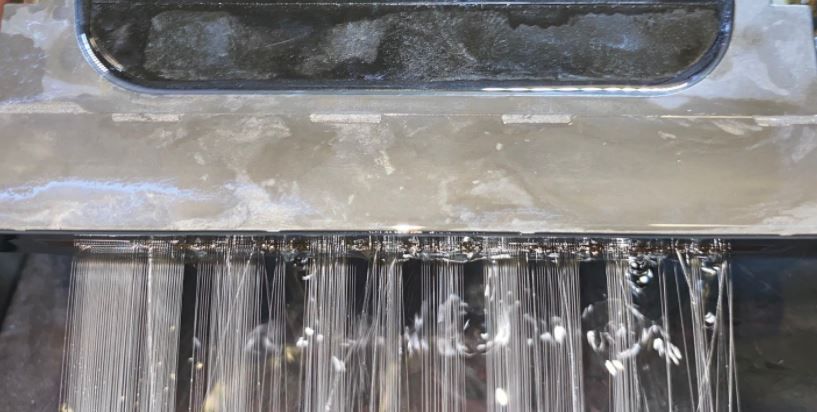

Your printhead is subjected to a thorough inspection before, during and after the cleaning process. In addition to regularly performing nozzle tests, we also assess the flow with waterfall tests and check the correct functioning of the electronic components.

Jet Repairing

Jet Repairing extends the lifespan of your printhead and maintains the highest level of quality, avoiding print artifacts. Upon arrival of the head, it will receive a pre-cleaning treatment, after which it will enter into the elaborate cleaning process.

Test Report

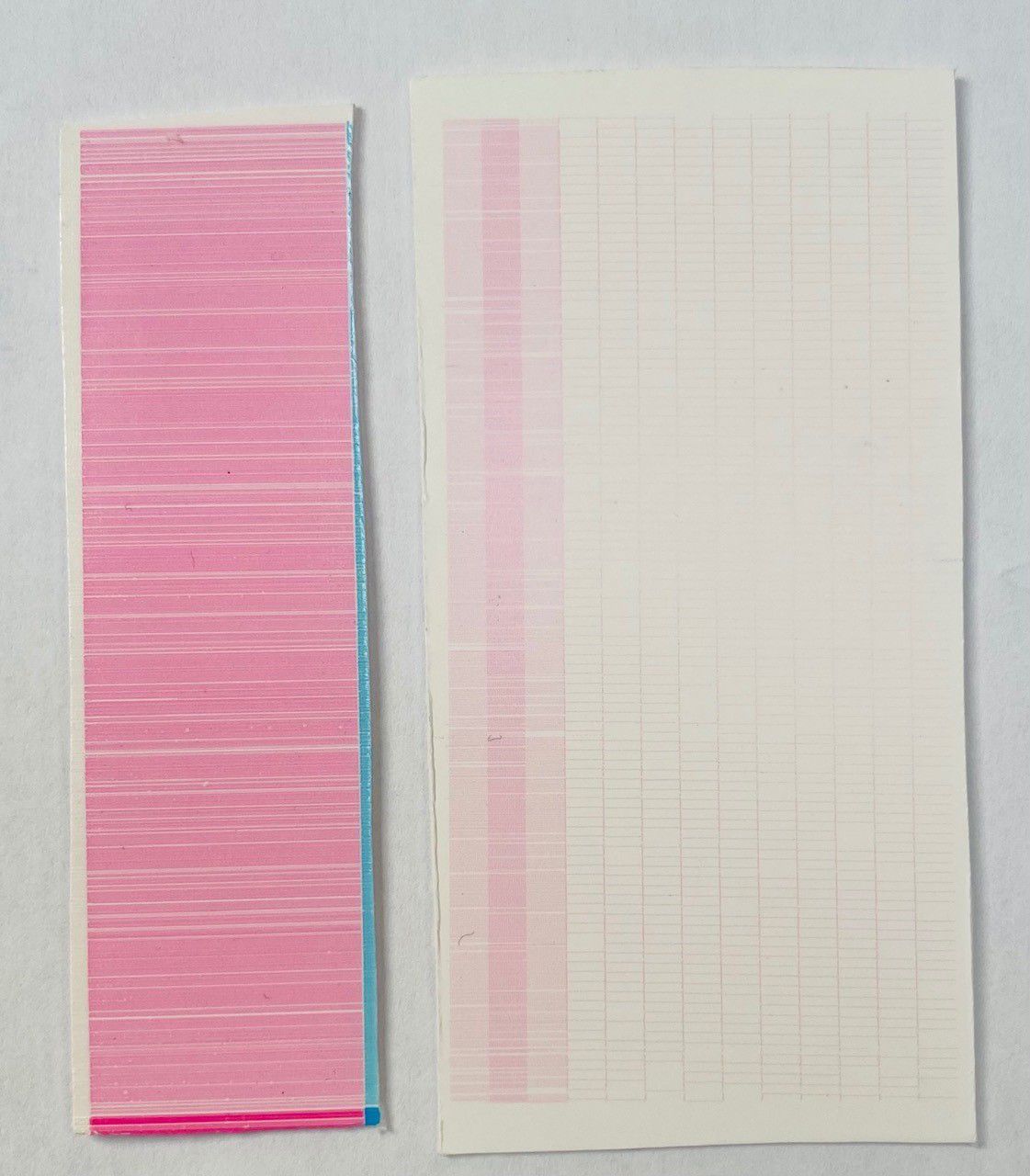

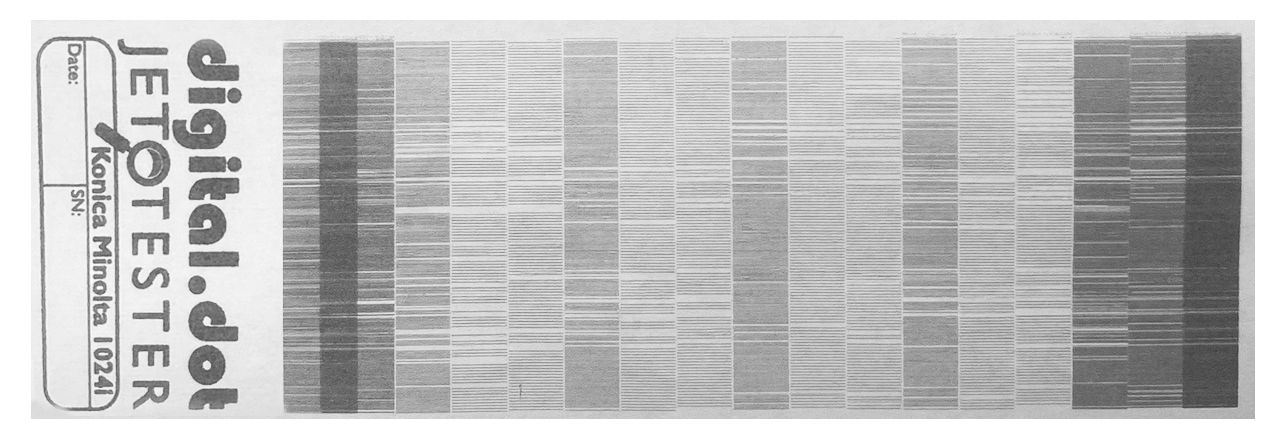

Every cleaned head will be delivered with a detailed report about the inspection outcome, the cleaning cycles and Initial and Final Waterfall and Nozzle tests.

What can we fix for you?

Missing nozzles

Some missing nozzels?

Missing half of your printhead's nozzle test?

Completely clogged?

Bad ink flow

Having a good nozzle test

but experiencing ink starvation during printing?

Stressed result

Getting misaligned images?

Overspray?

Grainy printresult?