Massivit 10000

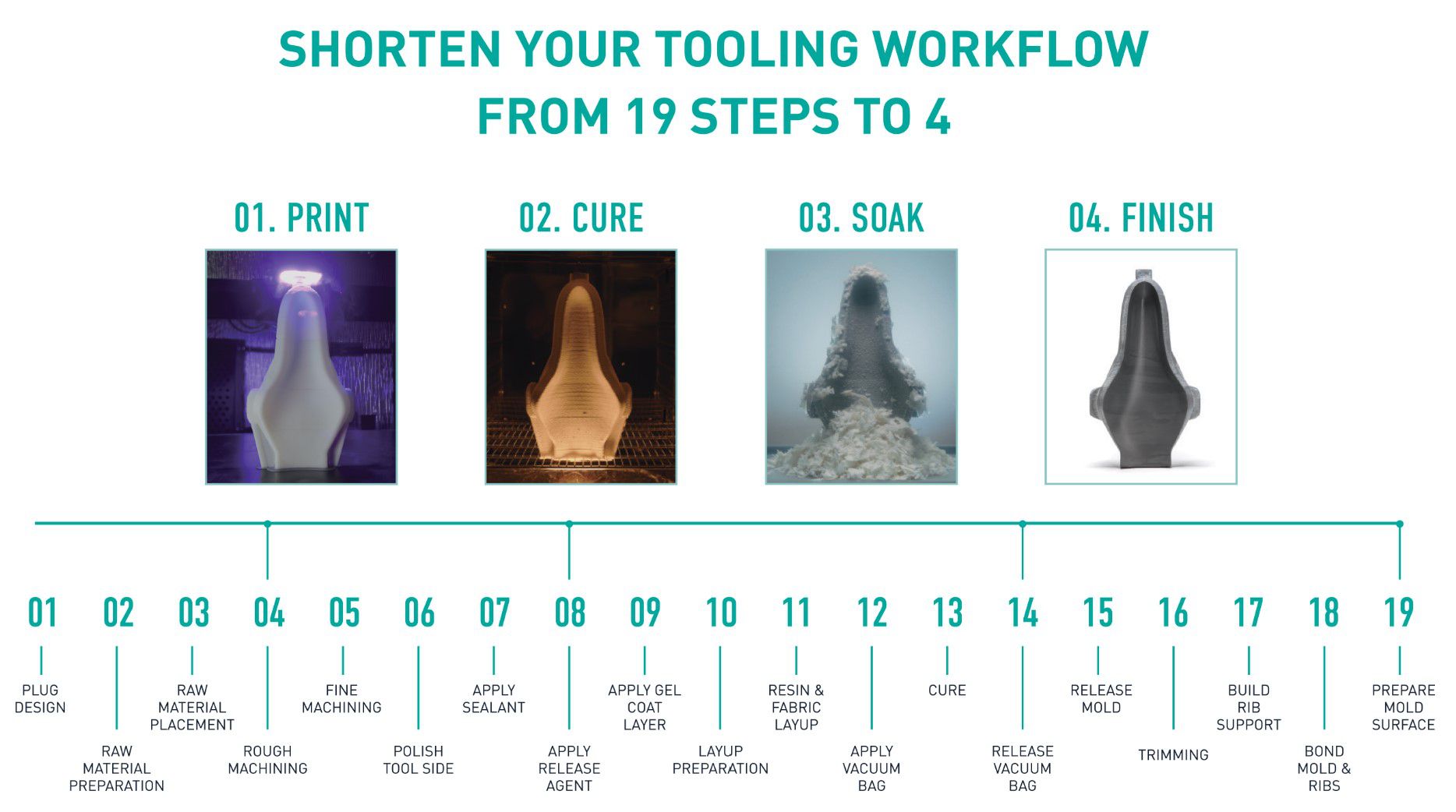

Based on Massivit 3D’s Cast In Motion (CIM) technology, the Massivit 10000 and Massivit 10000-G enable automated mold production and tooling for composite manufacturing. They empower composite fabricators to directly print industrial, complex molds within a matter of days, instead of weeks. This is enabled by a combination of ultra-fast, additive manufacturing technology and a high-performance casting material, CIM 500.

Cast In Motion brings to market the first, true isotropic 3D-printed mold.

Complex molds (including open and closed molds, tooling for Thermoforming, Resin Transfer Molding, and Reaction Injection Molding), mandrels, master tools, jigs and fixtures can all be digitally produced at high speed – serving a range of industries including automotive, rail, marine, construction, defense, aerospace, sporting goods, and bath ware.